Rolls-Royce Trent high-bypass turbofans. Launched RB-211-524L

| Type | Turbofan |

|---|---|

| National origin | United Kingdom |

| Manufacturer | Rolls-Royce Holdings |

| First run | August 1990 |

| Major applications | Airbus A330 Airbus A340-500 Airbus A340-600 Airbus A350 Airbus A380 Boeing 777 Boeing 787 |

| Developed from | Rolls-Royce RB211 |

| Variants | Rolls-Royce Trent 500 Rolls-Royce Trent 700 Rolls-Royce Trent 800 Rolls-Royce Trent 900 Rolls-Royce Trent 1000 Rolls-Royce Trent XWB Rolls-Royce Trent 7000 |

| Developed into | Rolls-Royce MT30 |

.

History Rolls-Royce Holdings plc Rolls-Royce Trent

Launched as the RB-211-524L

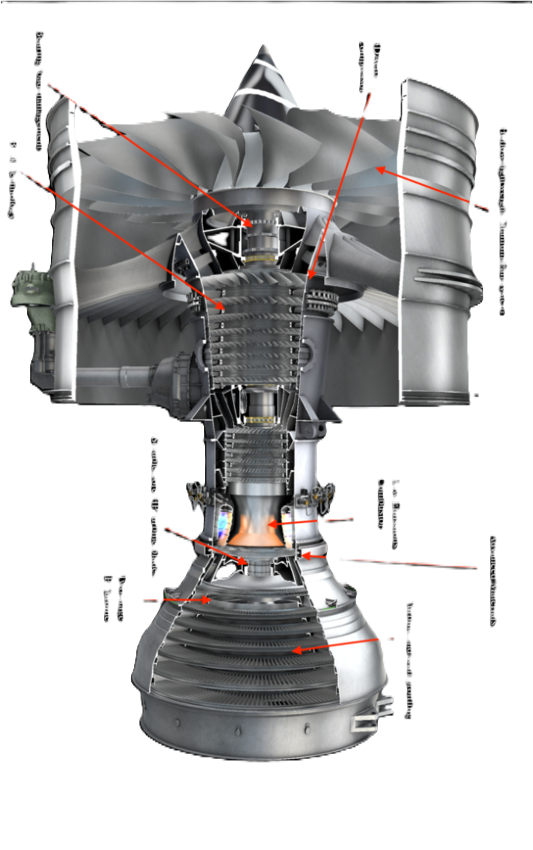

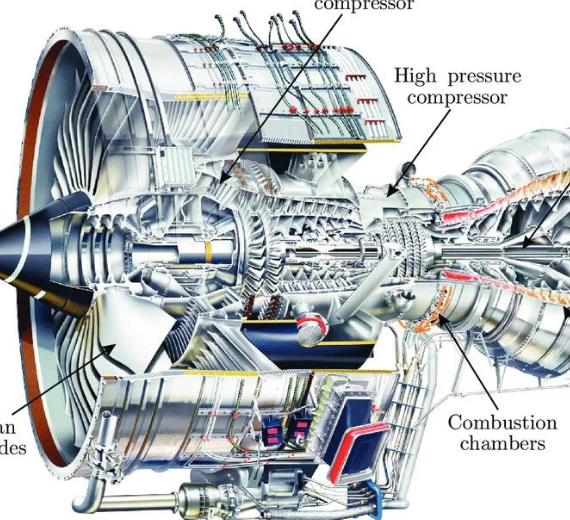

The Rolls-Royce Trent is a family of high-bypass turbofans produced by Rolls-Royce. It continues the three spool architecture of the RB211 with a maximum thrust ranging from 61,900 to 97,000 lbf (275 to 431 kN). Launched as the RB-211-524L in June 1988, the prototype first ran in August 1990. Its first variant is the Trent 700 introduced on the Airbus A330 in March 1995, then the Trent 800 for the Boeing 777 (1996), the Trent 500 for the A340 (2002), the Trent 900 for the A380 (2007), the Trent 1000 for the Boeing 787 (2011), the Trent XWB for the A350 (2015), and the Trent 7000 for the A330neo (2018). It has also marine and industrial variants like the RR MT30.

First Trent 600 / Trent 700

[edit]Main article: Rolls-Royce Trent 700

Rolls-Royce was studying a RB211 development for the Airbus A330 at its launch in June 1987. The Trent 700 was first selected by Cathay Pacific in April 1989, first ran in summer 1992, was certified in January 1994 and put into service in March 1995. Keeping the characteristic three-shaft architecture of the RB211, it is the first variant of the Trent family. With its 97.4 in (247 cm) fan for a 5:1 bypass ratio, it produces 300.3 to 316.3 kN (67,500-71,100 lbf) of thrust and reaches an overall pressure ratio of 36:1. It competes with the GE CF6-80E1 and the PW4000 to power the A330.

Trent XWB

Main article: Rolls-Royce Trent XWB

The Trent XWB was selected in July 2006 to power exclusively the Airbus A350 XWB. The first engine was run on 14 June 2010, it first flew on an Airbus A380 testbed on 18 February 2012, it was certified in early 2013, and it first flew on an A350 on 14 June 2013. It keeps the characteristic three-shaft layout of the Trent, with a 3.00 m (118 in) fan, an IP and HP spool. The XWB-84 generates up to 84,200 lbf (375 kN) of thrust and the XWB-97 up to 97,000 lbf (431 kN). The engine has a 9.6:1 bypass ratio and a 50:1 pressure ratio. It had its first in-flight shutdown on 11 September 2018, as the fleet accumulated 2.2 million flight hours. It is the most powerful among all Trent engines.

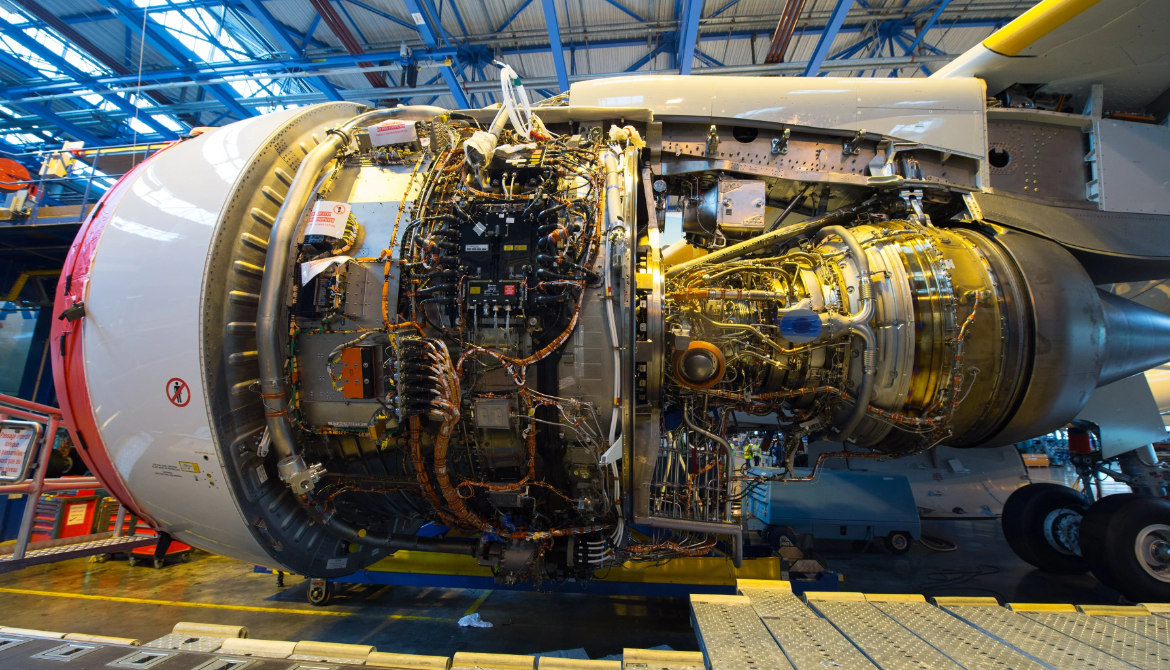

Photo Gallery

Rolls-Royce Holdings plc Rolls-Royce Trent

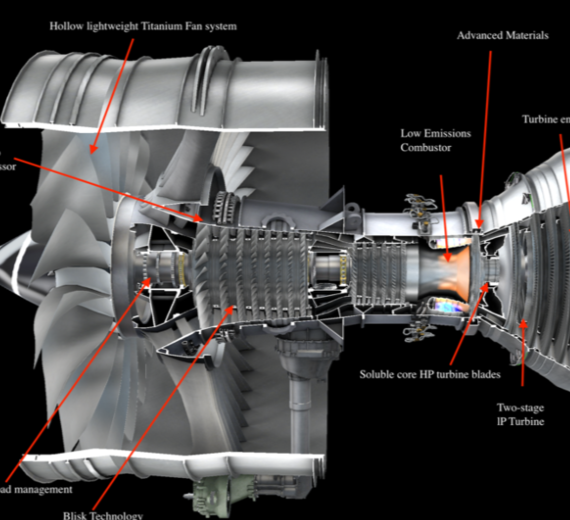

Launched as the Rolls-Royce Trent XWB

Rolls-Royce Holdings plc Rolls-Royce Trent

Launched as the Rolls-Royce Trent XWB

Powerplant

-

-

8 IPC, 6 HPC1 HPT, 2 IPT, 6 LPT 118 in (300 cm)22 blades

-

Year Introduction

-

2010

.

Links to Youtube & Others

Rolls Royce Trent Engines

Like its RB211 predecessor, the Trent uses a concentric three-spool design rather than a two-spool configuration. The Trent family keeps a similar layout, but each spool can be individually scaled and can rotate more closely to its optimal speed. The core noise levels and exhaust emissions are lower than those of the RB211.

Rolls-Royce Holdings plc RB-211-524L

Despite the RB211 success, the large civil turbofan market was dominated by General Electric and Pratt & Whitney, and Rolls-Royce share was only 8% when it was privatised in April 1987.

Youtube Link

It takes more than 20,000 components perfectly fitted together to build the world's most efficient aero engine, the Trent XWB. See how it is done at our Trent XWB assembly line in Dahlewitz, Germany

.png)